May 5

9.30-12.00

Cankarjev dom

Ljubljana, Slovenia

Conference Intelligent Façades

Interlacing of demands and human-centered design

Intelligent façades no longer represent an added value, but an inevitable necessity, so that a building can function properly. Advances in building technology, tightened requirements of the legislative bodies resulting from environmental causes, and higher expectations of various building users, push the development of an outer building skin even further. Façades are becoming adaptive, interactive and intelligent in order to meet the demands of time. Its design shall determine the benefits a facade can have on its occupants, its impact on the surrounding environment or its effect on building energy efficiency. It can, among other things, improve the natural lighting conditions of the interior space, contribute to unisturbed views to the outside, enable fresh flow of air, and harvest water or energy from the sun, among other aspects. And yet, a façade is still the face of a building which is shown to the outside world. It represents an exterior of a building which can now, with the evolvement of a building skin, be freer in expression and can be more communicative with the outside world.

Curator: Jernej Markelj PhD

Prof. Brian Cody;

Energy Design Cody; Austria, www.energydesign-cody.com

Brian Cody is university professor at Graz University of Technology and head of the Institute of Buildings and Energy since 2004. His focus in research, teaching and practice is on maximizing the energy performance of buildings and cities. Before his appointment in Graz, he was associate director of the international engineering consultancy Arup. He is founder and CEO of the consulting firm Energy Design Cody, which is responsible for the development of innovative energy and climate control concepts on construction projects all over the world. Professor Cody serves as member on many advisory boards and juries and is Visiting Professor at the University for Applied Arts in Vienna. He is author of the book “Form follows Energy” published in 2017.

LAB CITY CENTRALESUPÉLEC – ENGINEERING SCHOOL, ECOLE CENTRALE PARIS

Their involvement on this project started during the competition phase. They worked with OMA architects in Rotterdam to help them develop a new university campus building typology which achieves high energy performance by utilizing synergetic interactions between the various uses while creating a new form of campus space under a “climate envelope”. The building comprises teaching spaces, laboratories and offices, all enclosed within a climate envelope so that the in-between spaces form an indoor campus. Within the hall under the climate envelope, composed of a PTFE foil roof and glass façades, a macroclimate is created, largely by passive means, which is not as closely controlled as the internal environments within the laboratories and the offices. The roof design reacts to the requirements of the various spaces below by combining highly insulated opaque areas with transparent areas and optimizing their placement and distribution to reflect the distribution of the building program in the hall. The hall is a transitional space between the internal and external environments, supporting and enhancing the campus atmosphere and informal communication. The concepts developed work in the completed building to enhance both communication between people and synergetic energy flows between the many diversified uses under its roof, transferring surplus heat from the laboratories to spaces which require heat such as the offices.

DATA:

Location: Paris, France

Architect: OMA Office for Metropolitan Architecture

Building owner: Ecole Centrale Paris

Total floor area: 50 000 m2

Start date: 2012

Completion date: 2017

Service: Energy design concepts

Status: Completed

Rendering: OMA

Photos: Philippe Ruault

Renderings: OMA Office for Metropolitan Architecture

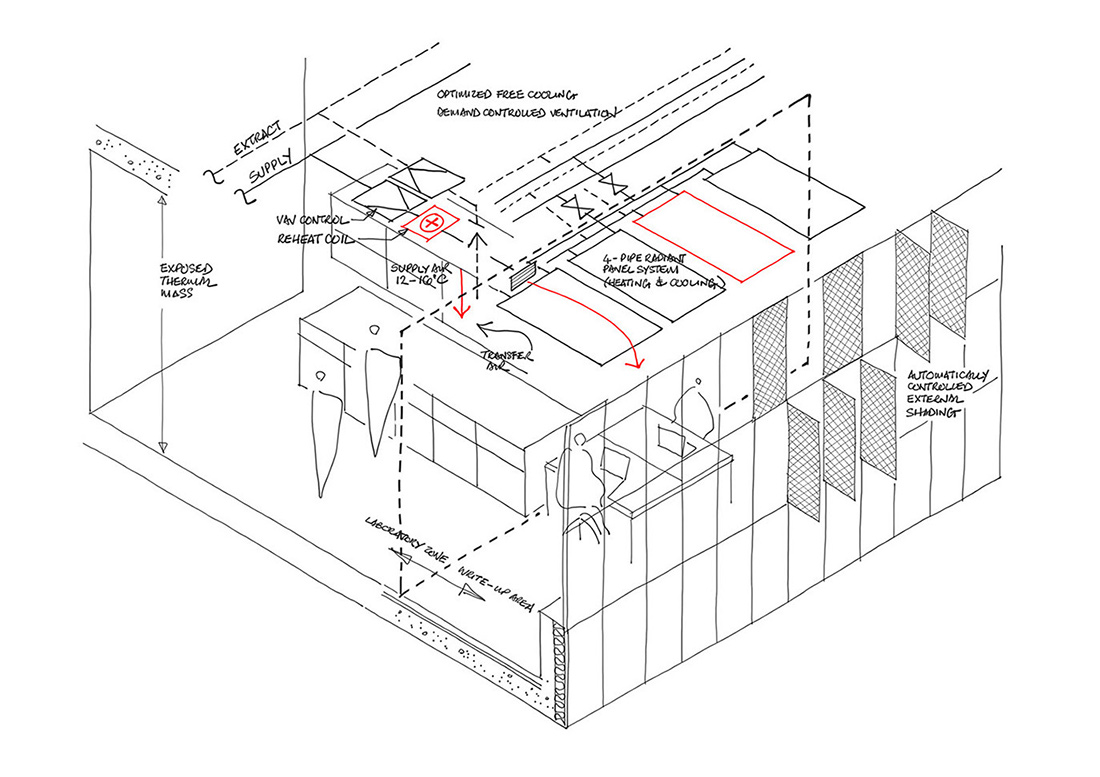

MED CAMPUS GRAZ

The exploitation of symbiotic relationships and synergies in the development of the energy systems is an important aspect of the concepts we developed for the new campus of the medical University of Graz, in collaboration with the architects Riegler Riewe. Deceptively simple strategies can save considerable amounts of energy and resources. In the laboratory areas, a system was developed which employs the supply of cooled air and the use of reheaters to meet the individual demands of the laboratory spaces instead of the conventional HVAC system type utilized in Central Europe with isothermal supply air and secondary cooling systems, ensuring a greater utilization of free cooling and thus saving thermal energy and increasing energy performance. The floor plan is so configured that the office spaces and write- up areas are positioned in the regions with the best daylight conditions. The daylight openings in the façades in the lab areas are provided at two levels, at mid-level to provide views at the write-up areas and at high level to provide daylight to the laboratories behind. The configuration and size of the openings in the façades depends on the specific location within the dense urban structure and the use of the spaces behind the façade. The offices are naturally ventilated and heated and cooled via suspended radiant ceiling panels. On account of wind considerations related to microclimate the buildings are orientated with the long axis running north-south. The external shading devices were therefore designed as automatically controlled vertically aligned perforated metal elements which allow daylight and views while blocking solar radiation.

DATA:

Location: Graz, Austria

Architect: Riegler Riewe Architects

Building owner: BIG Bundesimmobiliengesellschaft m.b.H.

Total floor area: 90 000 m2

Start date: 2010

Completion date: 2017

Service: Energy design concepts

Status: Completed

Dr. Sebastian Schmidt;

FIXIT GRUPPE; Germany; www.fixit-gruppe.com

Dr. rer. nat. Sebastian Schmidt, engineer and materials scientist. He has been working in the R&D department of the FIXIT GRUPPE as a project manager since 2020. His field of activity includes the supervision of Fixit 222 Aerogel high-performance insulating plaster, the development of new insulating plasters, testing and approval of building materials, the creation of environmental product declarations (EPDs) and participation in a committee on the topic of “recycling” of building materials.

The FIXIT GRUPPE has been in existence since September 2006 as the umbrella organisation for the five building material brands FIXIT, GREUTOL, HASIT, KREISEL and RÖFIX. With 67 locations in 18 European countries and around 2500 employees, the FIXIT GRUPPE is one of Europe’s leading system providers in the building materials sector.

At the end of 2021, the land area of the neighbourhood Novo Brdo measuring 4,8 ha witnessed finalization of the construction of 498 rental apartments, from 30 to 80 square metres each, in 18 buildings. This housing development is situated in Ljubljana Vič, between the Cesta na Vrhovce Road and Cesta na Brdo Road. The new neighbourhood consists of individual smaller buildings, the so called villa blocks and larger longitudinal blocks. The blocks are separated from each other and extend independently from North to South, they are divided by inner sidewalks and cycle tracks. These are higher standard buildings and flats providing a living space to a cohousing community of different generations. The well-being of the residents of this new neighbourhood will be provided by a safe open external area filled up with a new green system, playgrounds and connections with the existing green circle. Buildings all excel in high quality longlife facades, being carefully designed and professionally coordinated among the suppliers and contractors of individual construction elements, like facade components, insulation panel production, cladding installation, damp proofing installation and joint grouting. With the facade system StoneEtics ®50 of Röfix Slovenia, these buildings acquire aesthetic perfection, functionality and sustainability.

DATA:

Novo Brdo Neighbourhood

Architect: Dekleva Gregorič Architects

Size: 18 buildings

Facade: 25,000 m2 Röfix StoneEtics® and 8,000 m2 Röfix Etics

Photo: Matjaž Žnidaršič

The famous palace of Kazina, which was renovated at the end of 2021, shall be protected in future as an important local cultural monument. Proposal for Kazina being a local cultural monument was submitted by a group of conservators at the local unit of the Institute for the Protection of Cultural Heritage of Slovenia in Ljubljana. The »palace« represents one of some rarely preserved cases of a multipurpose public palace type, built in the first half of the 19th century, which already at that time was more than a meeting and association place. Actually, it became a true social forum of the nobility at first, and later of the townspeople as well. The Kazina Association had this building erected between 1835 and 1837, and its construction was led by the city master craftsman Venceslav Vadnav. In future, Kazina shall be entirely intended for the purposes of the Academy of Music. Reconstruction, that is renovation of the Kazina building was supervised by the Institute for the Protection of Cultural Heritage of Slovenia and on renovation proposal of the materials supplier Röfix Slovenia. We, in the company of Röfix Slovenia, strongly believe that maintenance of such buildings is our highest priority, so that these buildings shall be saved for future generations as witnesses of time. We endeavour that the project work is not reconstruction-oriented only, but also directed towards preservation of the historical substance. Röfix Slovenia can offer to professional personnel a great variety of historical mortars, base and final renders as well as coating products for restoration of historical architectural surfaces, as this was the case with the renovated Kazina palace in Ljubljana.

DATA:

Kazina of Ljubljana

Institute for the Protection of Cultural Heritage, Organisational Unit Ljubljana

Size: 6,000 m2 indoors and 2,500 m2 facade

Renovation system: Röfix Slovenia

Photo: Matjaž Žnidaršič

Dr. Philipp Lionel Molter

Studiomolter; Germany, www.philippmolter.com

Studiomolter is an interdisciplinary workshop researching and practicing in architecture and design. Inspired by curiosity they explore complexity and diversity of all scales in architecture and design focusing a scientific design research approach. Their method to design the built environment is based on a deep cultural as well as geographical research. The way they work reflects personal as well as social context in order to find the appropriate solution in an open and collaborative design research with architects, engineers, scientists and experts.

Philipp Lionel Molter is a former architect of Renzo Piano Building Workshop. Philipp founded his own studio in 2010 and realized award winning projects across all scales of the built environment. He was co-leading the Associate Professorship of Architectural Design and Building Envelope of the Technical University Munich before being appointed to full Professor for Architecture at IU International University. His principle research and teaching focuses on adaptive building envelopes and their thermal, visual and environmental performance. In this context, Philipp Lionel Molter is inventor and holds patents at the European Patent Office. For his doctoral thesis he was awarded with the Dr. Marschall Prize for an outstanding dissertation completed at the Department of Architecture of the Technische Universität München.

Based on his international background, Philipp Lionel Molter is author of books, scientific journal papers and peer reviewed articles. He is peer reviewer for scientific journals and has been lecturing all across Europe and in Australia. His work has been published by many authors in several magazines including wallpaper magazine, Frame magazine, DETAIL magazine and on TV.

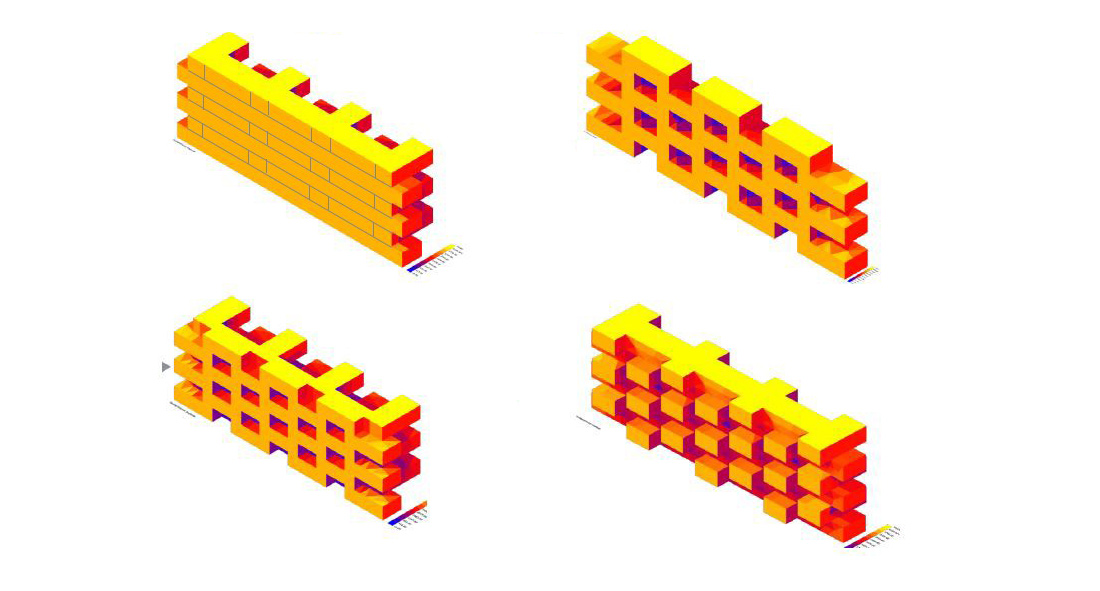

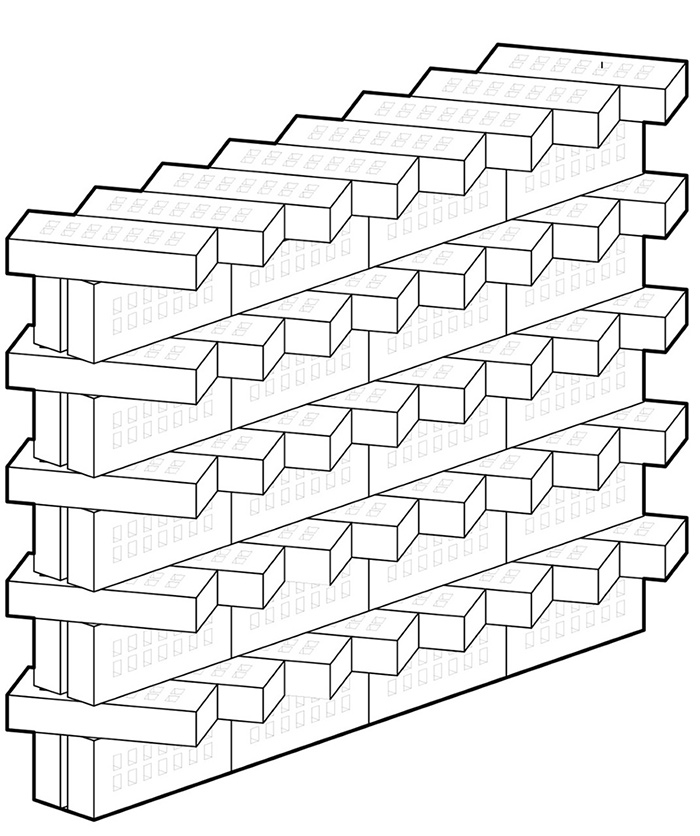

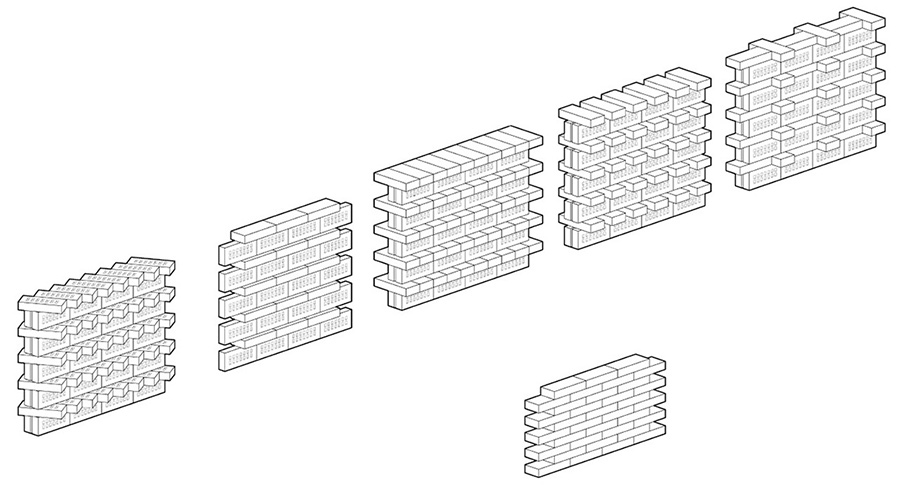

SELECTED RESEARCH PROJECTS: CLIMATE ACTIVE BRICKS

Brick has been proven to be one of the most widespread building materials worldwide and this is projected to continue. The adobe material, due to its high thermal capacity robustness and formal flexibility, can be assembled in different ways to control the thermal behaviour with self-shading or adding active interventions like extra moisture. Additionally, bricks as modular elements have the potential to be further studied in terms of geometric configurations to minimize or maximize their solar exposure for summer or winter scenarios as climate control elements. The potential of sprinkled bricks decreasing surface temperature of building envelopes can significantly contribute to an improved microclimate and improved urban heat island (UHI). This research investigates the potentials of different geometrical brick patterns and their behaviour on self-shading potential to reduce mean surface temperature of solar exposed brick walls. The study shaped in two layers including field measurements for geometric behaviour and evaporative cooling potential. The results are discussed and compared for 3 configurations of solid, extruded and perforated under varying boundary conditions over a day. Field measurements of solar exposed brick mockups are conducted in a range of experiments and their surface temperature monitored. The results show an average temperature difference of eight degrees Celsius between a straight solid wall and an optimized brick pattern featuring self-shading geometry. A second experiment showed eleven degrees of surface temperature difference combining self-shading brick geometry with irrigated surfaces.

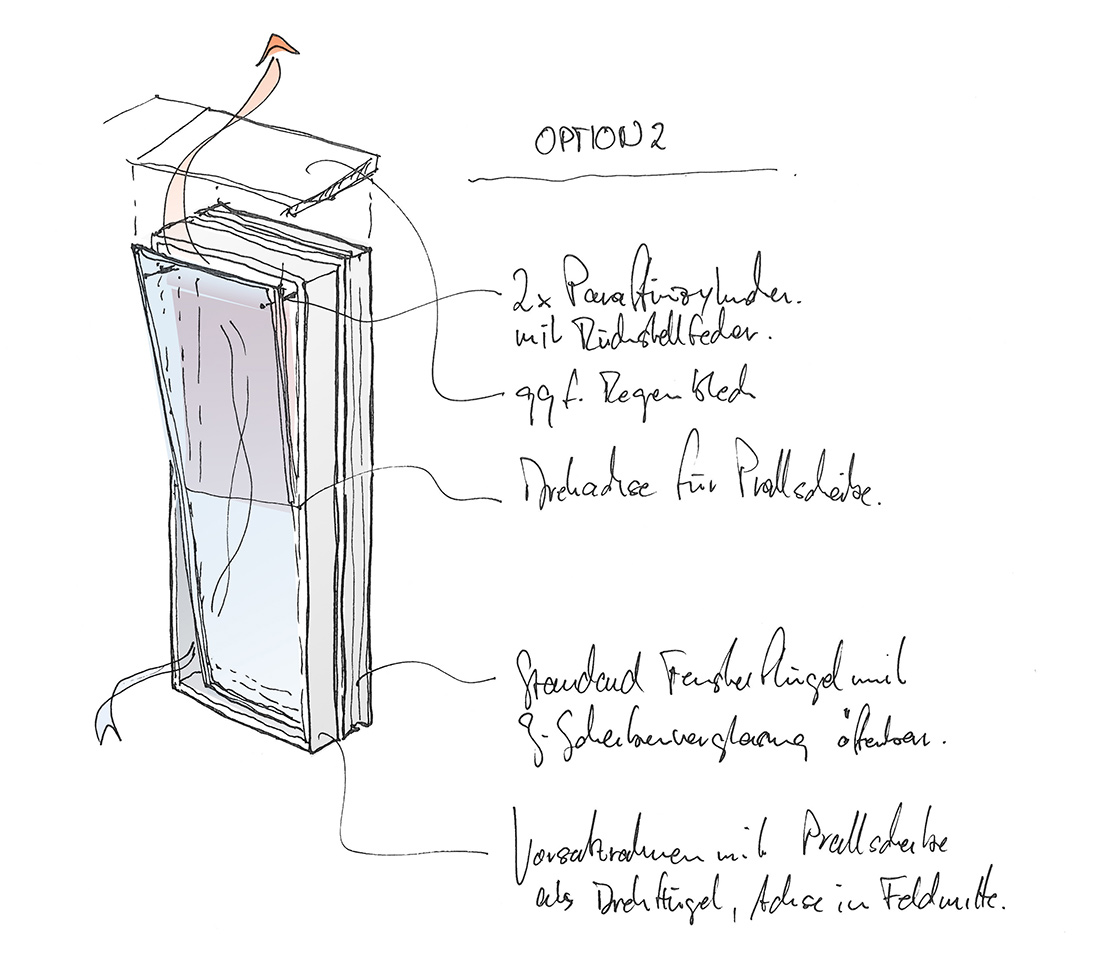

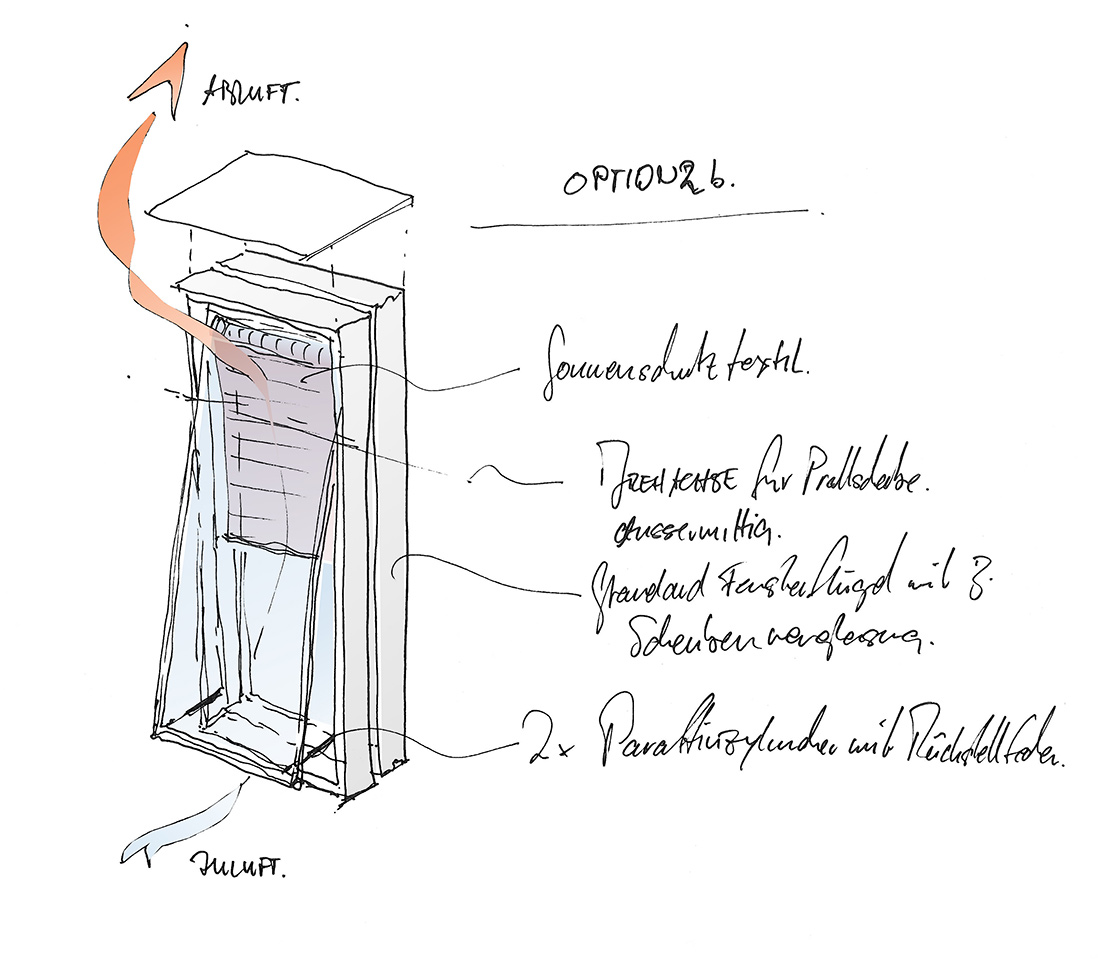

SELECTED RESEARCH PROJECTS: AUTOREACTIVE BUILDING ENVELOPES

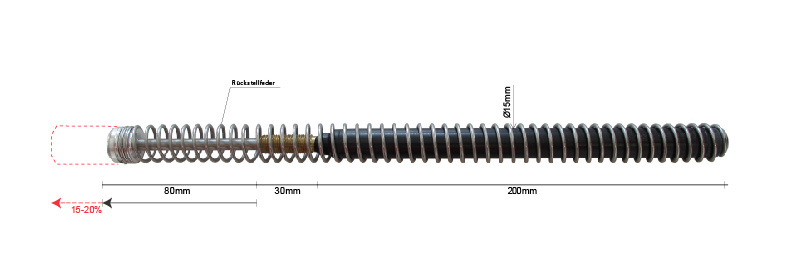

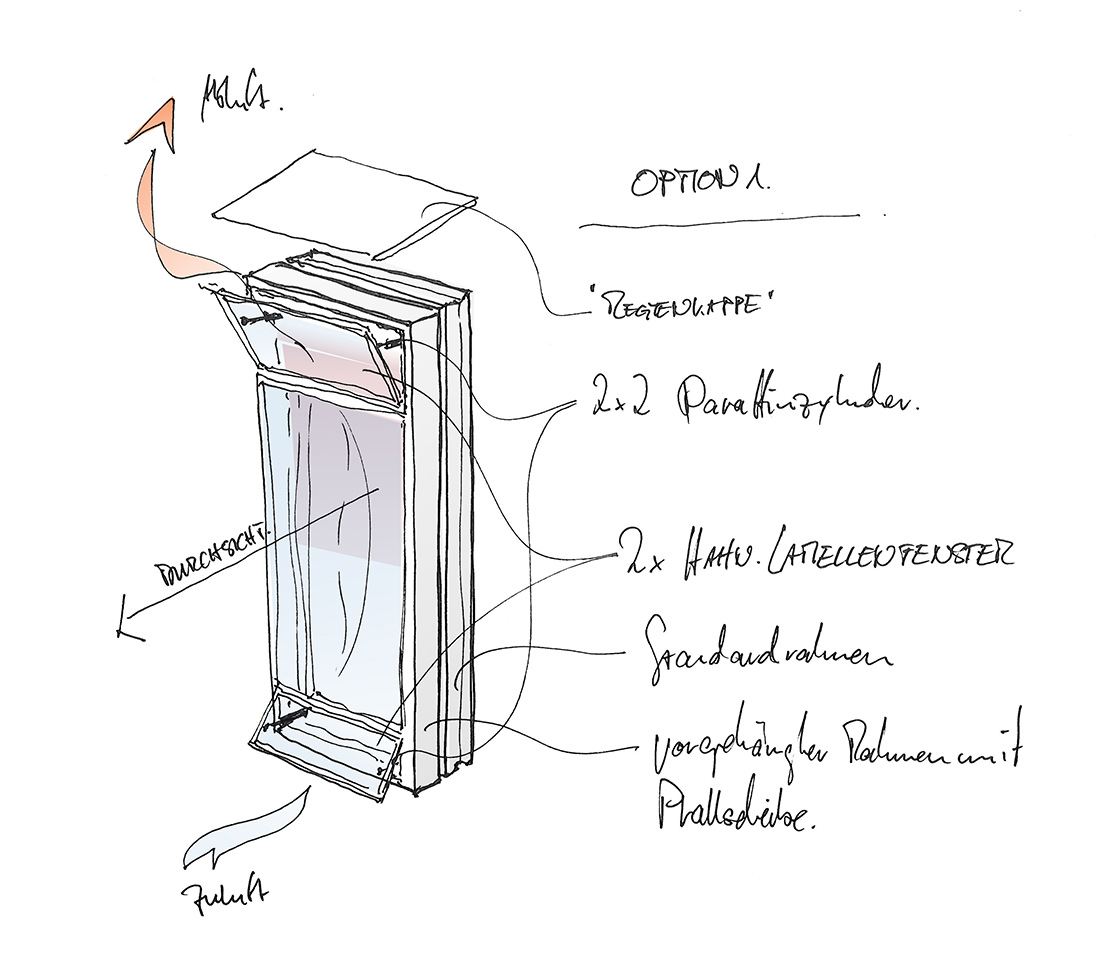

The heart of the Ventflex technology developed by Dr. Philipp Lionel Molter is a paraffin-filled thermal cylinder. The wax-oil mixture inside the cylinders expands when the temperature rises above a certain value. The increase in volume generates a pressure that pushes the cylinders apart like telescopes. If the temperature drops, they contract again. Until now, thermal cylinders have only been used to open and close ventilation slots in greenhouses. In his research project, which has just been completed, Molter is able to show that the technology is also suitable for cooling double-glazed facades efficiently, cost-effectively, energy-efficiently and without the need for complex electronic control systems.

Thermal cylinders control the low-tech facades

The elements of the new low-tech facade do not differ visually from conventional facade elements. However, the outer pane of the double-glazed box window is not fixed but connected to the frame at all four corners via the thermal cylinders. If the temperature between the panes rises above 23 degrees Celsius, the cylinders push the outer glass-front 5 cm outwards. The slot between the frame and pane allows cooler outside air to enter and naturally ventilate the space between the panes occupied by the heated sun protection. If the temperature drops below 23 degrees, the gap closes again automatically. The reaction time is only a few minutes. In winter, the facade module remains closed on cold days to prevent the offices from cooling down.

Positive energy balance

Simulations at the Chair of Building Technology and Climate Responsive Design at the Technical University of Munich show that the new low-tech concept is very efficient: Compared with modern facades, up to 50% of the energy required for heating and cooling can be saved. For high-rise buildings from the 1970s and 1980s, which have not yet been renovated and therefore consume a lot of energy, the savings can be considerably greater.

Yasemin Yalcin-Chauca

2226; Germany, www.2226.eu

Yasemin Yalcın-Chauca was born in 1988 in Bregenz, Austria. After studying architecture at the Technical University in Innsbruck, she designed boutiques in Europe, Asia and the USA for the St. Gallen fashion house Akris. From May 2016 she worked at Baumschlager Eberle Architekten in Dietmar Eberle’s team on concepts, competitions and publications. In 2018 she completed her Masters in Collective Housing at ETH Zurich/UPM Madrid. Since 2020 she has been repeatedly invited as a guest professor at the Collective Housing program. Since January 2020 she has been the managing director of company 2226, which is part of the Baumschlager Eberle group. Photo portrait: Baumschlager Eberle Architekten

Though modern buildings tend to use less and less energy, the cost of servicing and maintaining them is growing ever higher. An international landmark project, Baumschlager Eberle Architekten’s the new head office sought to break new ground both in defining Baumschlager Eberle Architekten’s signature style and in its association with a technical revolution that saw it dispense to a large extent with technology.

Visionary thinking for the future. Part universal prototype, part example to the world, 2226 asks the question: What is the role for human intervention in an office building that has dispensed with all its heating, ventilation and cooling technology? The answer lies at 2226, an HQ building set in Lustenau’s Millennium Park.

In a building that is a functioning part of its environment rather than just “architecture”, the choice of name is no accident: the ambient temperature inside is a constant 22°C to 26°C. The only heat sources it contains are there for other purposes, from the users themselves – every individual gives off an average of 80 watts of heat – to lights, computers and photocopiers, even coffee machines.

Living in harmony with the elements. 2226’s perfect interior climate generates a perceptible feeling of wellbeing by harnessing the angle of the sun and the flow of the wind, just as its high-ceilinged rooms and clean, simple lines create a generous, light-filled atmosphere. Behind the space lies a technical vision based on the insights gained over more than 35 years of architectural practice at Baumschlager Eberle Architekten. 2226 impresses on several fronts – its minimalist approach, its low construction and energy costs and a natural climate that produces a pleasant working environment.

One building, four seasons, a host of ideas. In winter, the warmth generated by the building’s various heat sources is used to maintain an agreeable room temperature. Internally hinged, sensor-controlled ventilation panels in the windows open automatically as soon as the CO2 content or the temperature in the room starts to rise. During the heat of summer, the panels open at night to cool 2226 with natural draughts. The air conditioning system’s sensors can also be overridden, enabling the ventilation panels to be operated manually.

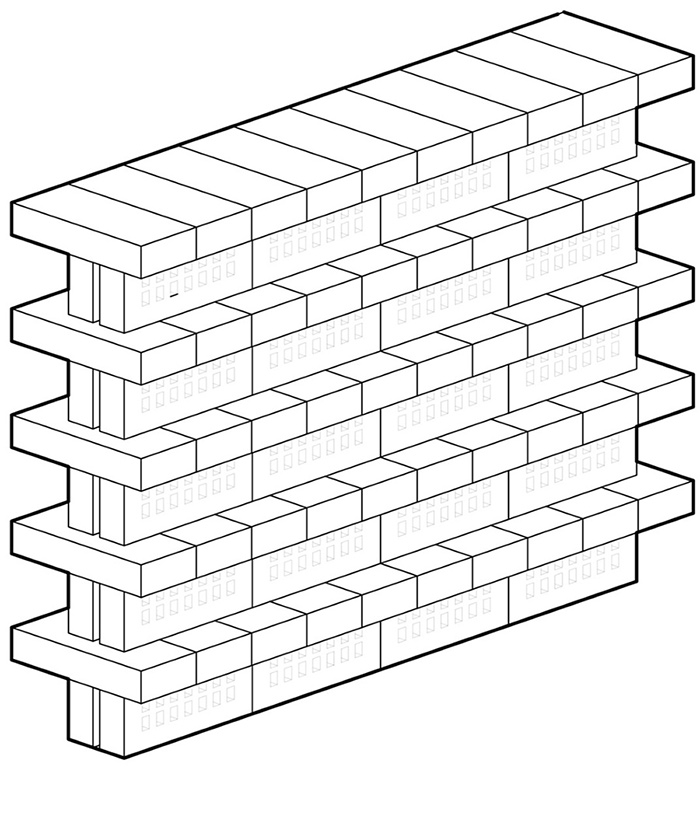

The necessary level of temperature stability in the building is achieved by its own thermal mass thanks to exterior walls that consist of 38cm of load-bearing and 38cm of insulating brickwork. The walls are covered in a smooth lime-render inside and out, natural sunlight making the exterior finish harder and more dirt-repellent over time. 2226 represents a first glance into the future of a new concept, and with its high-quality materials and estimated lifetime of 200 years it will be around for some time to come. In the shorter term, however, 2226 will no doubt continue to be seen as an exemplar of a new way of thinking.

Client: AD Vermietung AG

Landscape design: Baumschlager Eberle Architekten

Photography: Eduard Hueber, archphoto © Baumschlager Eberle Architekten

Loction: Lustenau, Austria

Site area: 4,037 m²

Area of building: 543 m²

Gross floor area: 3,200 m2

Floor area: 2,421 m²

Completion: 2013

Judicious land use. Following the removal of two derelict houses, Graf Immobilien GmbH were planning to rebuild on their sloping site. In a context characterised by a mix of housing estates and individually built family homes, the plan was to create a multi-occupancy development comprising eight units and an underground car park that would mark the architectural transition between large estates and individual properties. The 2226 building concept was chosen to ensure maximum sustainability.

In terms of urban design, the subtly staggered heights and façades play a mediating role. The building comprises eight identical 3-bedroomed units connected by two stairwells. Each apartment has its own terrace or balcony and a basement provides underground car parking and individual cellar space. The basement is constructed in concrete, the over-ground floors in brick with a lime plaster façade to meet the calls for a smart, upmarket building. The rear half of the building is set into the slope, while the outdoor space – a series of embankments, walls, terraces and footpaths – is planted with standard trees, shrubs and other greenery.

Climate-clever architecture. Designed on the 2226 principle, the building does away with the need for conventional heating. Temperature and CO2-controlled window casements provide highly effective, low-loss ventilation and the building’s inherent density, compact structure and carefully dimensioned window-to-wall ratio area create an advanced envelope with optimum thermal inertia. The heat given off by the building’s residents, its lighting and the domestic appliances it contains is sufficient to maintain a base temperature of approx. 22°C, while temperature- and CO2-controlled windows keep ventilation losses to a minimum. Hot water in the residential units is provided by a backup system centred on an array of roof-mounted solar panels. Alongside hot water, it also provides additional individual heating via infrared panels in the living areas. Any excess energy is stored in a battery.

Client: Graf Immobilien GmbH Dornbirn, Austria

Landscape design: Baumschlager Eberle Architekten

Interior design: Baumschlager Eberle Architekten

Photography: René Dürr

Location: Dornbirn, Austria

Site area: 1,108 m2

Area of building: 357 m2

Gross floor area: 714 m2 | GF 357 m2 | 1F 357 m2

Floor area: 507 m2 rented living area

Completion: 2020

Innovative new build trumps renovation – Emmer’s Crinolbau building, a reminder of the town’s industrial past, was in serious need of renovation and slated for replacement. Due to its historical significance, the owners worked closely with both the town authorities and Luzern’s historic monuments service on the project. Our brief was to design a contemporary, cost-effective building and our response, 2226 Emmenweid, a manifesto for sustainable building in terms of both urban planning and energy efficiency. After detailed examination of the place and its history, what emerged was an innovative, self-assured structure that blends elegantly into the existing environment, enhancing its identity. The new build follows the size and roofline of its predecessor, referencing its past in the subtly offset façade. An energy-efficient first for Switzerland, 2226 Emmenweid provides high levels of indoor comfort without heating, cooling or mechanical ventilation. Its name refers to the interior temperature: a constant 22 to 26°C. Temperature stability is achieved through double-skinned walls almost 80cm thick and the restrained use of glass.

Swiss first follows Austrian model – In 2013, in Lustenau, Austria, Baumschlager Eberle Architekten built themselves a new headquarter building that requires no ventilation, heating and air conditioning technology. Energy efficiency is often achieved by means of high-tech solutions, but the 2226 concept is based on the principles of building physics. The temperatures inside the building are obtained thanks to the heat generated by its users, equipment and lighting. Sensor-controlled ventilation panels control temperature and CO2 levels and ensure a comfortable environment whatever the season. An architectural statement in a historical setting – Despite references to its predecessor, the new build with its pale plaster finish and generous windows dominates its older neighbours. High construction standards inside as well as out – A central service core with adjacent kitchenettes and sanitary facilities leaves a broad strip running around the outside of the building for the modular office space. Fit-out and décor are upmarket and restrained, another quality that contributes to 2226 Emmenweid’s significance as a sustainable building.

Client: BRUN Real Estate AG Emmenbrücke, Switzerland

Landscape design: USUS Landschaftsarchitektur AG

Interior design: Baumschlager Eberle Architekten

Photography: René Dürr

Location: Emmenbrücke, Switzerland

Site area: 1,076 m²

Area of building: 560 m²

Gross floor area: 2,815 m²

Floor area: 2,169 m²

Completion: 2018

2226 concept meets Bregenz Forest tradition – The construction of a new preventive and social medicine centre on behalf of aks gesundheit GmbH for the Bregenz Forest was planned for Lingenau. The building was to house four flats, an underground garage and spacious treatment rooms and office space and the design to emphasise the village’s characteristic features, take account of local regional building traditions and reflect their potential for the future. The compact, stand-alone building is carefully positioned on both the site and the slope. Its plasticity creates a dialogue with the open space in front of it and the terrace to the side, shaping the site as a whole. The urban feel of the outside space contrasts with the clear message of the façade: this is a typically Bregenz Forest building. The façade features spruce-shingle cladding and sliding wooden shutters; the roof is made of anthracite-coloured metal panels. The shingling conveys a sense of solidity and, together with the exterior cornicing above the shutters, makes a clear reference to local building techniques. The building perpetuates local cultural values: precision, durability and the avoidance of superfluity.

How the 2226 concept works – Despite having no heating, ventilation or cooling, 2226 Lingenau provides comfortable temperatures of between 22 and 26°C all year round. This is achieved thanks to the solidity of the structure and optimum insulation of the building envelope and by means of efficient window ventilation with a combined temperature and CO2-level control system that can be manually overridden at any time. As a result, the building is pleasantly warm in winter and relatively cool in summer with good air quality whatever the season. High standards of comfort and views of the surrounding area – The highly distinctive nature of the design is also visible inside. The service cores on the two floors that accommodate the treatment centre itself can be expanded and contracted in a metaphor that mirrors the beating of a heart. This flexibility also significantly increases the quality of the patient waiting areas, offering views of the village and surrounding countryside. These exterior views are provided by specially designed windows with narrow ventilation panels that are recessed in the 50cm-thick brick walls.

Client: aks gesundheit GmbH

Landscape design: Baumschlager Eberle Architekten

Interior design: Baumschlager Eberle Architekten

Photography: Eduard Hueber, archphoto © Baumschlager Eberle Architekten

Location: Lingenau, Austria

Site area: 1,925 m²

Area of building: 589 m²

Gross foor area: 2,300 m²

Floor area: 1,848 m²

Completion: 2019

Jochen Lam

Transsolar KlimaEngineering; Germany, www.transsolar.com

Transsolar is an international climate engineering firm determined to create exceptional, highly comfortable indoor and outdoor spaces with a positive environmental impact. They believe that the very measures taken to create remarkable architecture can simultaneously enhance human experience and minimize resource use. To them, sustainability is not separate from design, but an indispensable component that enhances the experience of the built environment.

They are vision facilitators, idea generators, and design integrators. Their engineers are not just experts in basic physical principles; their creativity enables the collaboration necessary to develop deeply integrated comfort and energy concepts. Beginning from a project’s earliest conception, they work alongside the client, architect, design team, and the most vital participants of all – the occupants. They study the seasonal behaviour of sun, wind, heat, light and other energy flows in and around the building, and formulate concepts based on the complex interdependence of the local climate, user needs, architectural design and engineered systems.

Jochen Lam studied mechanical engineering at the University of Stuttgart and joined Transsolar’s Stuttgart office in 2013. In 2016 he worked in Transsolar New York office for one year. Jochen is part of the TRNSYS development team and an expert in thermal modelling of buildings and systems. Besides his consulting work, he gives lectures and workshops at European universities.

SEEZEITLODGE, HOTEL & SPA AT LAKE BOSTAL, NOHFELDEN, GERMANY

In June 2017, a new 4-star hotel opened on the shores of Bostalsee, a lake and eponymous recreational area in Saar land. The hotel houses 100 rooms and suites, a 2.000 m2 spa, a restaurant, a bar, and conference facilities. To run a luxury hotel, a beautiful view to the lake is not enough. The customer experience must also be exceptional. Transsolar’s role was critical in creating high quality comfort and cost-effective operation. One target of the project is to demonstrate that such comfort can be achieved without increasing the energy demand. Through an iterative design process and the use of thermal, day light and CFD simulations, Transsolar worked with the architect and client to develop the energy and comfort concept. A challenge of the project was to maintain an unobstructed view of the lake while limiting the solar heat gains in summer. The hotel room balconies and the exterior suspended wooden lamella were optimized for sun protection, day light and views. Motorized awnings are installed on the ground floor to provide shade for the patio, lobby, restaurant and event rooms while allowing for unobstructed views and free passage. In the hotel rooms, thermally activated concrete ceilings provide the basic heating and cooling. During winter, the room temperature can be controlled via convectors. Guests can also decide how fresh air enters the room: they may either open the balcony door and windows or they can switch on the bathroom fan which draws outdoor air through façade trickle vents. A gas-powered combined heat-and-powerplant provides heat and electricity for the base load; the waste heat from the chiller is used to pre heat the domestic hot water and the pool water in the spa area.

DATA:

Client: HotelKultur

GFA: 129,000 ft / 12,000 m

Architect: GRAFT Gesellschaft von Architekten

Mechanical: ZWP Ingenieur-AG

Structural: Knippers Helbig

Interior Design: Nicolay Architektur & Design

Photos: Michael Moser

ALNATURA CAMPUS, DARMSTADT, GERMANY

The new Alnatura Headquarters in Darmstadt opened 2019. The “Bürowelt” (“officeworld”) consists of offices, a canteen and a conference area. Besides providing a good indoor climate, special emphasis is placed on “simplicity”: more quality by reduction. This was achieved primarily through the design. The planning team focused on reducing the expenses for technical equipment by introducing passive approaches while ensuring a high user comfort. They evaluated the embodied energy of the new building and adopted resource-friendly solutions for the components. As a result, the team developed a high-performance building with optimized indoor comfort while using natural materials such as the rammed earth façade or the wooden roof construction. The vertical façades are shaded externally. The east and west facades are glazed floor-to-ceiling and combined with bright surfaces, an atrium and north-facing skylights provide optimal day light supply. The artificial lighting is controlled by occupancy and ambient brightness. The building is ventilated naturally, preconditioning fresh air via earth ducts and then distributing it to the offices via displacement ventilation. In addition, the occupants can individually open windows for fresh outside air. Operable openings in the atrium roof drive natural cross-ventilation and exhaust used air. The ventilation system is equipped with CO2 sensors and can be supported mechanically if needed. To reduce heating and cooling demand solar gains are utilized and heat loss is reduced. In summer the thermal mass is cooled via nighttime air flushing and subsequently

acts as cooling source throughout the day. A radiant system, which is integrated in the rammed earth walls facing the room, can be activated as support if necessary. A geothermal system with bore holes provides heating and cooling.

DATA:

Client: Alnatura Campus GmbH

Completion: 2019

GFA: 10,000 m²

Architects: haas cook zemmrich STUDIO 2050

Structural: Knippers & Helbig

HVAC: Henne & Walter

Building physics: KNP

Landscape architect: Atelier Dreiseitl

Rammed Earth Lehm Ton Erde

Photos: Roland Halbe