This project has won an international design competition for a new building complex that will house office and laboratories. The complex will cover an area of 5,000 square meters. The client asked for a sustainable office building that could meet the highest architectural and environmental standards.

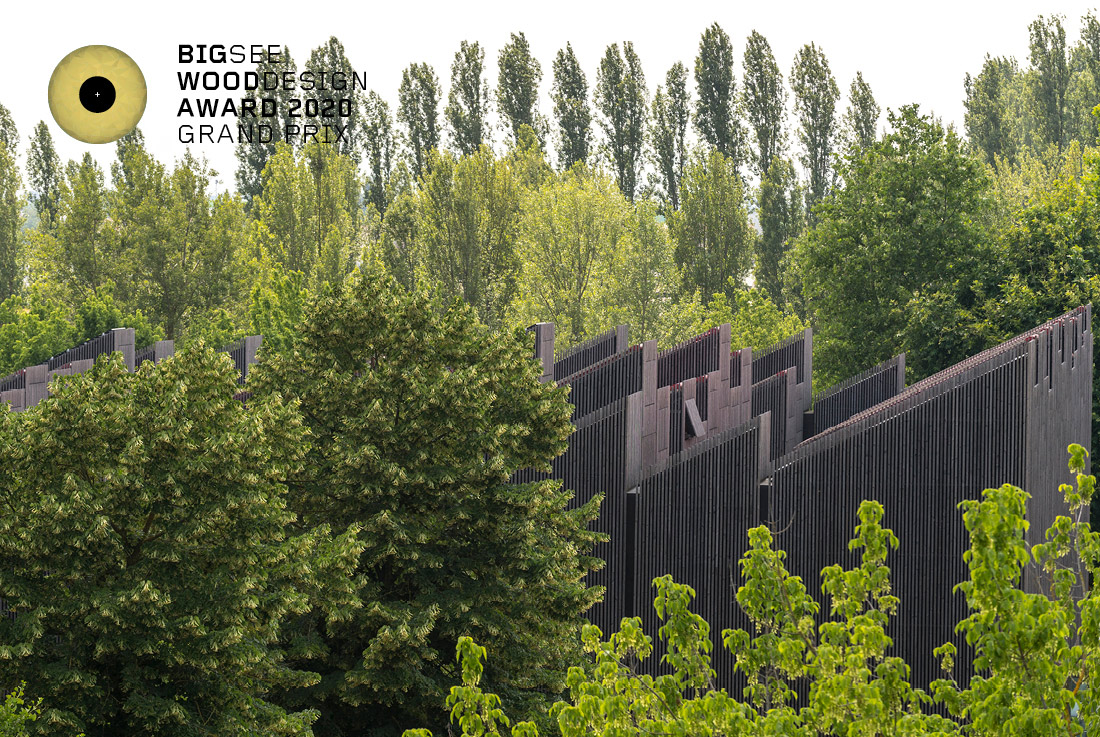

“The ARPAE building in Ferrara explores the relationship between form and performance, that makes it the first hybrid public building in Italy. It houses the Regional Agency for Environmental, and is located in a particular climatic context. We are just outside the city of Ferrara, whose climate oscillates between two extremes: hot and humid in the summer, cold and damp in winter. Only in spring do we have a normal relationship between temperature and humidity.

I am pointing this out because the definition of sustainability— which still needs to be worked out—is not only concerned with aesthetics, but also relationships of empathy with places, climate, and people. The roofing consists in a series of 112 chimneys that have a twofold function: controlling light distribution, and enhancing natural ventilation. The chimneys work differently in summer and in winter. In the summertime, the chimney effect expels air in the upper part of the building, thus avoiding the buildup of heat, whereas in winter, they work like greenhouses: accumulating solar heat that gets pumped back inside the building. This entire process is cost-free, and needs no technological add-ons. This is the idea I would like to explore: investing more in analysis and simulation rather than on technology alone, creating a hybrid building. This is what best represents the true change leading to a new, ecological age, that transforms environmental risks related to climate emergency to an opportunity of development. The building is entirely made of wood and constructed on site. It is built around an inner patio, which also functions as a climatic garden. Building with wood, controlling natural light and ventilation, using technology sparingly, and focusing on well being, comfort, and quality of space: these are the ingredients for defining sustainability as a new form of visible and invisible beauty”. (The project described by Mario Cucinella)

Climate Strategies

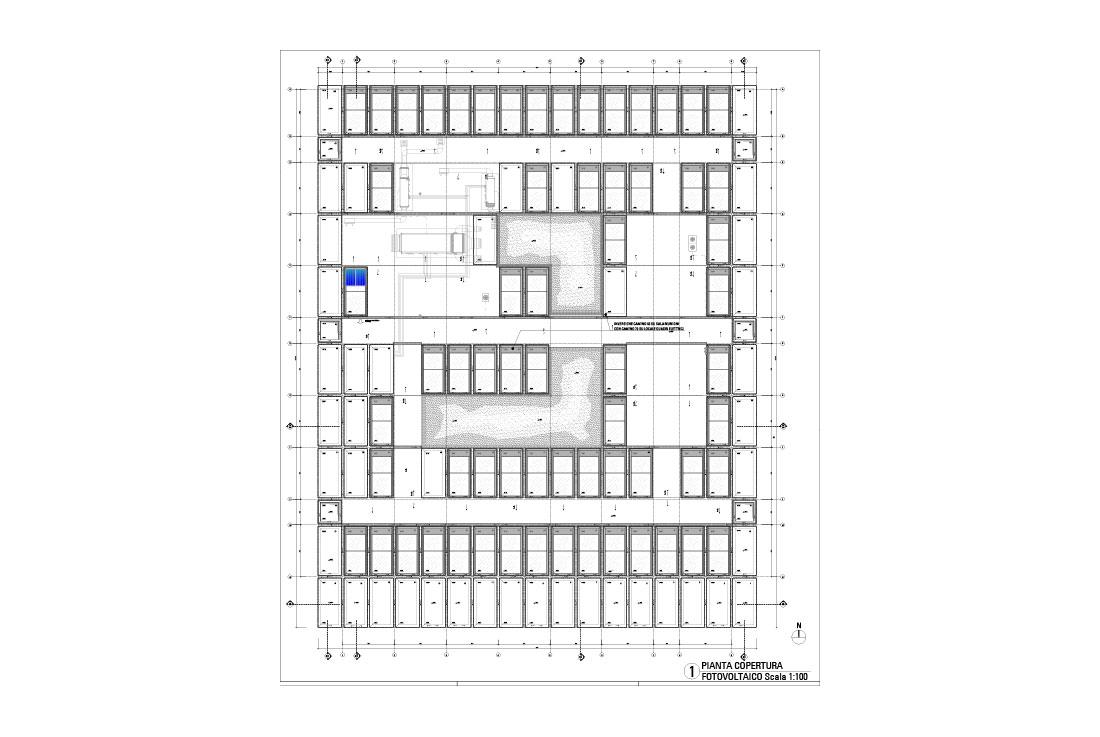

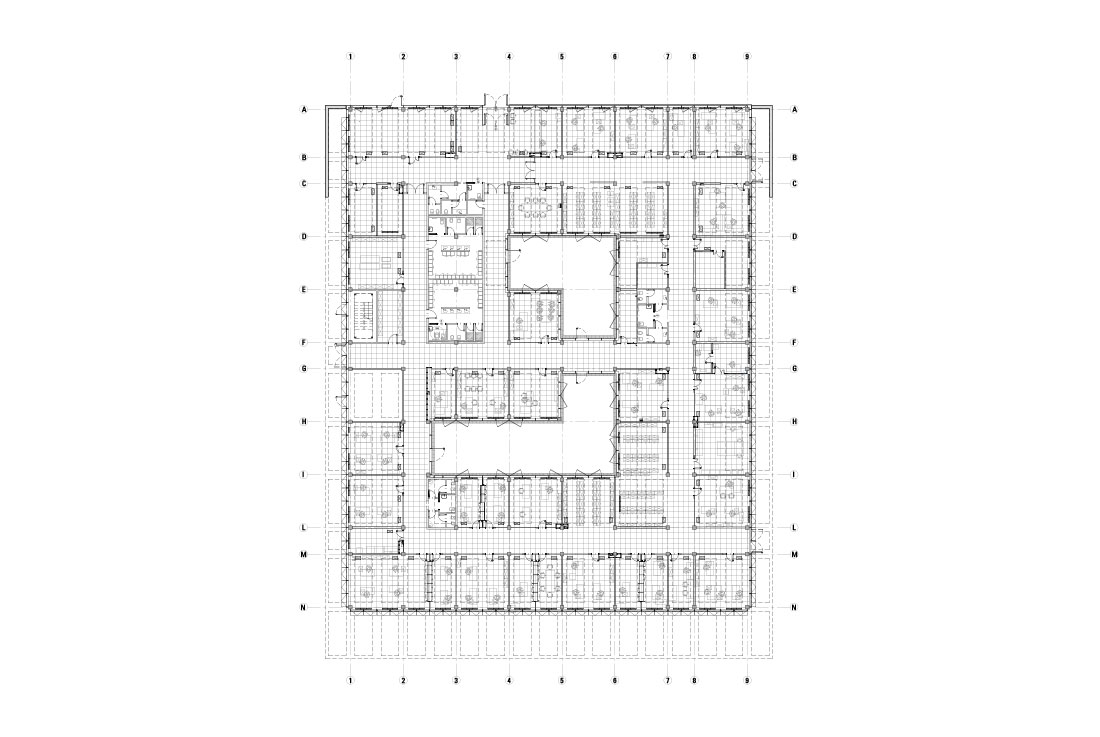

The implemented strategies turn the building into a bioclimatic filter that aims at an annual consumption below 100 Kwh/m2 for both heating and cooling. This is possible thanks to the combination of active and passive bioclimatic strategies and technical systems. Passive strategies include natural ventilation, which is promoted thanks to air circulation generated by shafts and temperature gradients, thereby increasing thermal comfort during the summer and mid seasons. The creation of internal courtyards (in both the new and the existing building) generates a microclimate that can lower the temperature through sunlight control, vegetation and non-mineral surfaces. Moreover, it creates openings in the façade and roof, allowing for better air extraction and movement thanks to the stack effect. All this is ensured by pressure switch-controlled automatic openings. This way, the roof plays a crucial role.

Suitably oriented, it becomes a zenithal natural light shaft, a hot air extractor during the summer, and a solar capturing surface (a true solar collector) during the winter. About 300 m2 of photovoltaic panels are placed on some of the shafts on the roof, which are optimally oriented to maximize solar energy efficiency. Moreover, solar panels have been added to the roof of the existing building for domestic hot water production. This type of architecture helps exploit zenithal natural lighting as much as possible – especially important to meet the requirements of the activities that the building will house – by calibrating opaque and transparent parts both on the roof and the façade according to needs.

Technical systems and structures

The whole building – starting from its shape – is designed to minimize the use of technical systems. In any case, most of the energy required for their operation comes from renewable sources. The necessary thermal and cooling energy is produced for exclusive use thanks to two multipurpose groundwater-based units, which can simultaneously produce hot and chilled water during any time of the year, using the electricity produced by the photovoltaic system, thereby eliminating emissions into the atmosphere.

Domestic hot water is produced by the solar panels on the roof and partly by the central heating system. A control system helps exploit solar energy to the fullest. Secondary heating – essential when solar energy is not available – meets any additional space heating requirement. All offices, meeting rooms, and archives are equipped with an air- and water-based air conditioning system. In the offices, primary air is ensured by air handling units provided with a high-efficiency recovery system that can operate in free cooling mode when the outdoor temperature allows. The laboratory is equipped with a variable air volume (VAV) ventilation system to compensate for the air extracted by the laboratory hoods in operation, keeping the room under negative pressure compared to the surrounding areas in any operating mode.

Moreover, a separate rainwater harvesting and condensate reuse system provides water for toilet flushing. The load-bearing structure of the building is made of glulam and consists of straight rectangular cross-section structural elements made using spruce wood boards in accordance with the EN 14080 and DIN 1052 standards. The structure is quite simple and consists of a post and beam frame supporting the overlying shaft deck. The main beams with a 60×20 cm cross-section are arranged on two rails along the shorter side of the building. The posts on the 6×3 m structural framework are made of spruce glulam and have a 29×29 cm cross-section and an average height of 4.5 m. The posts bear directly on the foundation, which forms an inverted beam grid. The spruce glulam used for the posts falls within strength class GL32 or GL36, as stipulated in the EN 14080 standard. The metalwork is functional to the structural nodes and suitably protected against corrosion. Stiffening and bracing systems, as well as neoprene bearing pads, are also in place. The shafts that dominate three sides of the building overhang six meters on the southern side and three on the longer eastern and western sides. The overhangs are supported by the beam and post frame and a system of steel rods within the shaft deck.

Wood

The new building is entirely made of wood with an on-site dry construction system, which means that reducing water consumption starts in the construction site. Moreover, the dry assembly system facilitates maintenance and the replacement of elements throughout the building’s lifespan. From a formal point of view, wood allows the building to integrate perfectly into the surrounding vegetation-rich landscape typical of the Po Valley area. In addition to the spruce glulam structure, there is the deck on which the shafts are built, which consists of a timber stud and joist frame. Steel elements connect all wooden elements and these to the reinforced concrete foundation. The inside of the deck is filled with a double fiberboard panel (10cm 160kg/mc, + 10cm 270Kg/ mc) with an overall thickness of 200 mm. This “package” is held together by OSB panels on both sides, which not only facilitate transport to the construction site but also serve as bracing structures. A framework of vertical 3×3 m listels is fixed to the OSB panels on the inside of the shafts. 3-S spruce plywood panels are then fastened to the framework. These plywood panels, which are 22 mm thick and are impregnated with white dye, form the final internal finish. On the outside, a framework of horizontal 3×3 m listels is fastened to the OSB panels. Staggered vertical listels with varying thickness are then fixed along the horizontal direction of the framework, thereby adding movement to the façade.

Credits

Authors

Mario Cucinella Architects

Team

Mario Cucinella, Michele Olivieri, Giulio Desiderio, Chiara Tomassi, Francesco Barone, Caterina Maciocco, Antonella Maggiore, Giulio Pisciotti, Luca Stramigioli, Alessio Rocco, Debora Venturi

Model makers

Natalino Roveri, Yuri Costantini, Andrea Genovesi

Structural engineering

Tecnopolis S.p.A.

Wooden structures

SWS Engineering

Bioclimatic analysis

TIFS Ingegneria

Electrical engineering

Tecnopolis S.p.A.

3D Rendering

Engram studio

Client

Arpae Ferrara

Photos

Moreno Maggi

Year

2006-2018

Location

Ferrara, Italy

Area

5,000 m2

Project Partners

Montelaghi S.p.A. (construction company), Novello Ambiente S.p.A. (wood), Base S.p.A. (fixtures)