Office principals Andreas Reeg and Marc Dufour-Feronce place special attention on the local connection of their buildings. This also applies to the choices of materials they use. With the Cork screw house, they developed a base out of rammed concrete for the lower ground living levels. The outdoor walls of the long stretched pool are also lined with the material. The base was supposed to look and feel “like it was excavated”, explains architect Andreas Reeg. The century old construction material is traditionally applied in layers and then manually compacted. This results in an open, porous and characterful textured surface.

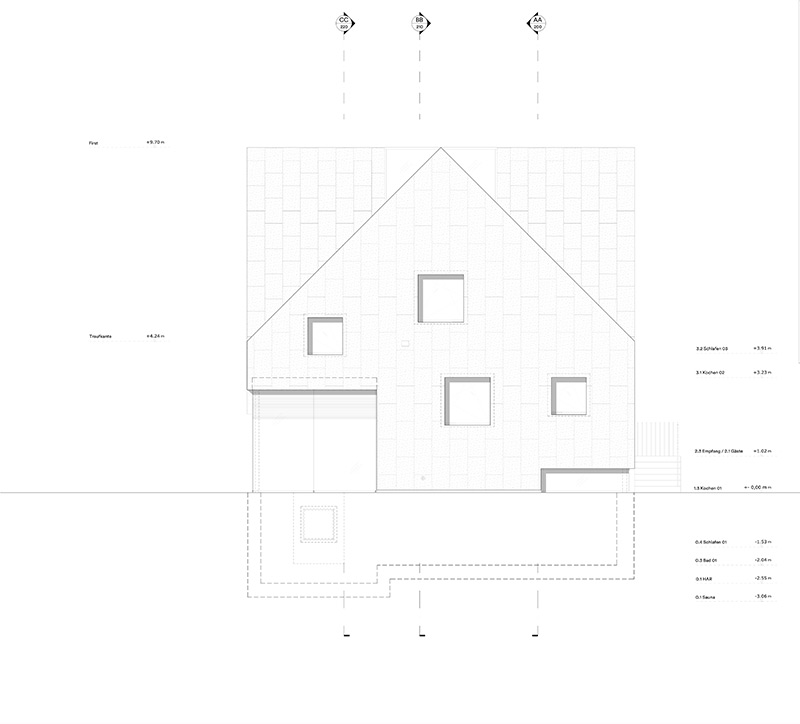

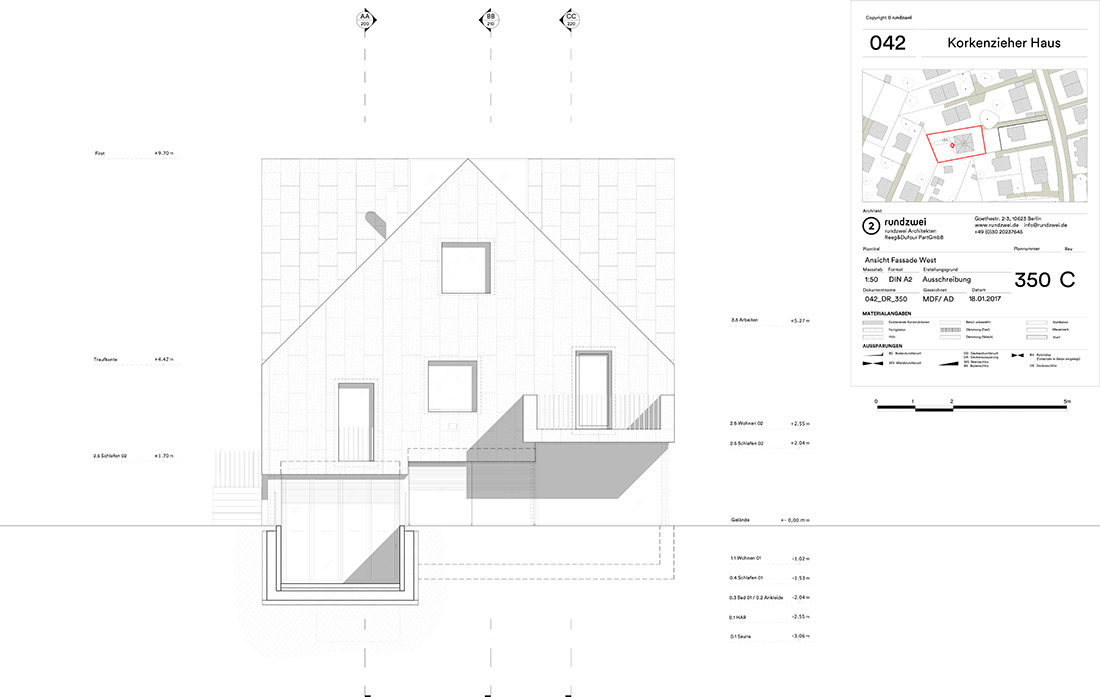

Maximising usable area by lowering floors and introducing multi split-levels

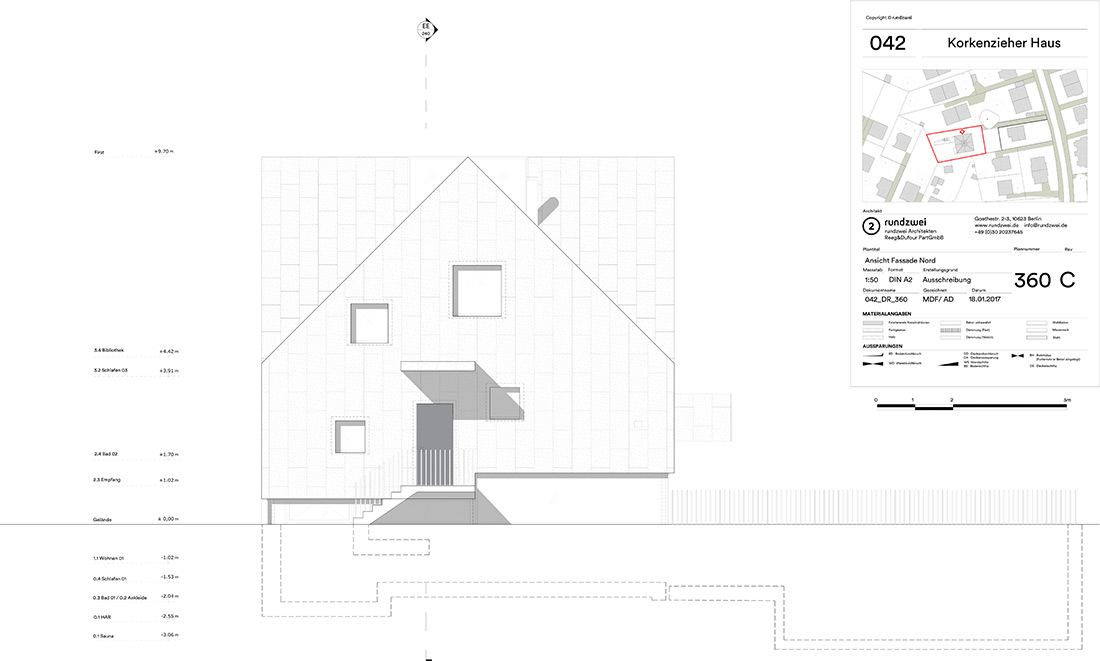

Although the local planning regulations allow for a maximum floor size of 100m², by lowering the base floors and arranging the upper floors in multiple split-levels, the architects have maximised the gross floor area to over 320m². The planning concept of two part construction – base and top – was maintained for the material selection: the levels below ground are built in rammed concrete with the upper levels framed in timber.

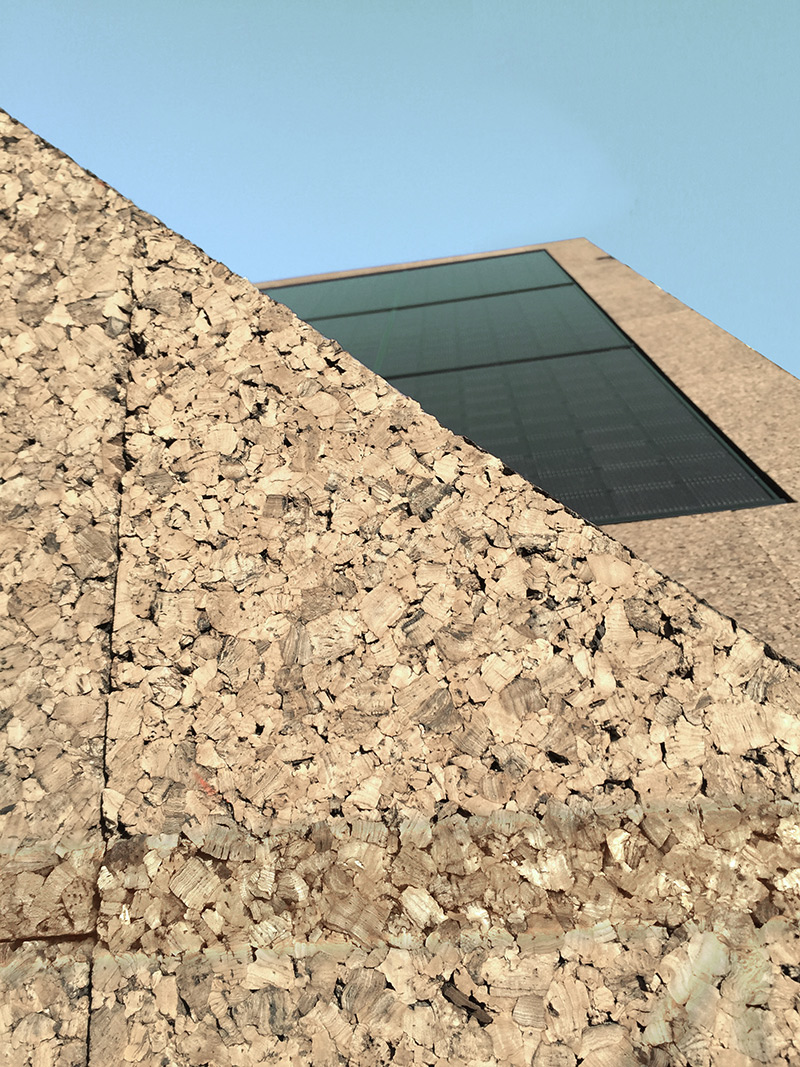

Cork panels on facade and roof

On the ground floor large scale glass elements fill the interior with daylight. The facades above, as well as the roof surfaces, with exception of a few windows and the solar panels, are completely clad with cork. The architects found the unusual material in Portugal. As a by-product of the cork production process for bottles, granulated cork waste is formed into facade panels under pressure and heat. During this process the natural resins of the cork are released, binding the granulate thereby creating a light weight and durable cladding material through sustainable methods. The resulting cork facade panels are naturally weather and mould resistant without any artificial additives. Natural cork has very high insulation values and is well suited to use as a monolithic facade cladding. The choice of this material contributes significantly to the energy efficiency and sustainability of the building. Cork also provides good acoustic insulation and reduces the sound of dripping rain. Initially it was through the client’s interest in achieving good acoustic performance that the architects came across this unusual choice of material.

Natural construction materials, natural ventilation

During the construction process the architects abstained from the use of chemical adhesives and construction foam. Wood fibre and cellulose insulation materials were used in addition to the insulating cork panels. Humidity absorbing materials such as timber and gypsum fibre boards with permeable paints allow for a natural room climate. As a result the building doesn’t need an active ventilation system despite the very low energy standard. Through a stratified heat storage system supplemented by roof integrated solar panels, the heating supply is almost self-sufficient adding to the efficiency of the building’s overall performance

Flexible living

The house was planned for three. The base of the building incorporates a bedroom next to the living and kitchen area. This room has direct access to the exterior sunken pool. This feature stretches from the house into the garden while maintaining privacy from the neighbours through the surrounding rammed concrete walls. The smaller rooms on the upper levels are accessed via the central circulating stair. They are partially connected and in the future could be used as studio apartments. To provide future flexibility, the architects have allowed space and structural provision for a potential second entrance in the fa軋de.

What makes this project one-of-a-kind?

The young office rundzwei Architekten has realised an unusual residence with a cork facade and roof. A base of rammed concrete lies below the ground level. Above, skilfully stacked split levels, which allow for flexible use, are accessed via a central, atrium like staircase.

Credits

Architecture

rundzwei Architekten

Team

Luca Di Carlo, Ana Domenti, Marc Dufour-Feronce and Andreas Reeg

Client

Private

Year of completion

2018

Location

Berlin-Staaken, Germany

Total area

320 m2

Site area

1.117 m2

Photos

rundzwei Architekten; Gui Rebelo

Project Partners

Ingenieurbüro Krawitz, Berlin, Enegieberater Land Brandenburg ELB, Brandenburg, Geologe Andreas Zill, Berlin, EFG Sandler, Zimmerei Johannsen, Timm Fensterbau, Caerus Construction, Seidel Metallbau, Seeigel Pooltechnik, Theo’s Handwerk, Marotzke Malereibetrieb, Schmidt Fußbodentechnik, Tischlerei Rothe, Sanitherm Priebe, Isik Elektrotechnik, Katsch Markisen